If you’ve been searching for vinyl windows that offer both sleek, modern aesthetics and exceptional performance, your wait is over. The new TotalSeal™ UltraSlim Series combines a minimalist frame profile with the proven energy efficiency and reliability of high-performance vinyl. Designed for Canadian homes, it delivers a clean, contemporary look with more glass, less frame, and no visible gasket — all without sacrificing insulation or durability.

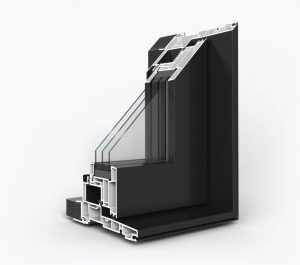

Frame Depth: Precisely 4-9/16 inches

Frame Width: Just 2-7/8 inches – significantly slimmer than industry standards

Frame Design: Ultra-flat profile with seamless appearance

Hidden Gasket Technology: Innovative concealed rubber gasket system for a smooth, uninterrupted surface

"What makes the UltraSlim Series truly revolutionary is its multi-chambered internal design. While traditional vinyl windows sacrifice structural integrity for slimmer profiles, we've engineered a frame that maintains exceptional strength despite its minimal visual footprint." — Daniel Klein, Project Manager

The engineering principle behind this achievement lies in our optimized internal chamber configuration. These chambers serve a dual purpose: enhancing thermal efficiency while simultaneously reinforcing the structural integrity of the frame.

Unlike mechanically fastened window systems, the UltraSlim Series features:

The UltraSlim Series is specifically engineered to accommodate the revolutionary FlexScreen® system:

The technical sophistication of the UltraSlim Series extends far beyond its appearance.

Our testing revealed that slim profiles typically sacrifice structural stability. We’ve countered this with:

"During development, we subjected the UltraSlim Series to extreme thermal cycling tests, simulating decades of Canadian seasonal changes. The fusion-welded corners maintained their structural integrity even after the equivalent of 25 years of expansion and contraction cycles." — Eugene Siukayev, Project Manager

The security system represents a significant advancement over conventional single-point locks:

The UltraSlim Series features premium Encore operators with:

Energy efficiency isn’t just marketing with the UltraSlim Series—it’s measurable, tested, and certified.

The multi-chambered frame design creates thermal breaks that significantly reduce heat transfer:

| Glass Configuration | Gas Fill | U-Factor | SHGC | VT | UV Blockage | Sound Attenuation |

| LowE-180 | 97% Argon | 0.26 | 0.69 | 0.78 | 71% | STC 29 |

| LowE-272 | 97% Argon | 0.28 | 0.41 | 0.70 | 84% | STC 29 |

| LowE-366 | 97% Argon | 0.27 | 0.27 | 0.65 | 95% | STC 29 |

| LowE-i89 (dual coating) | 97% Argon | 0.20 | 0.27 | 0.65 | 95% | STC 29 |

| Laminated option | 97% Argon | 0.26 | 0.27 | 0.64 | 99% | STC 35 |

All glass units feature:

"Our glass selection process is highly technical. For each coating option, we analyze the electromagnetic spectrum transmission characteristics across UV, visible light, and infrared wavelengths. This allows us to optimize each configuration for specific climate challenges and orientation needs." — Cherry Jian, Sales Consultant

For a deeper dive into glass configurations, visit our article on double pane vs triple pane windows.

The UltraSlim Series has undergone rigorous testing to CAN/CSA-A440 standards with impressive results:

Learn more about condensation prevention in our detailed guide on condensation on windows.

These technical specifications translate into tangible benefits for Canadian homeowners.

Based on computational modeling for a typical 2,000 sq ft home in the Greater Toronto Area:

Sound transmission characteristics:

| Customization Parameter | Available Specifications |

| Frame Colors | Standard UPVC white, beige, bronze; Acrylic overlay finishes (14 options); Custom paint finishes to any RAL color code |

| Glass Options | Clear, obscure (4 patterns), Low-E (4 formulations), laminated (0.030", 0.060", 0.090" PVB interlayer options) |

| Grid Configurations | Between-glass (5/16", 5/8", 1" widths); Simulated divided lite (SDL); True divided lite (TDL) |

| Hardware Finishes | White, black, satin nickel, oil-rubbed bronze, brushed chrome, antique brass |

Screen compatibility: Standard screens not compatible; requires FlexScreen® system

As an engineering-led company founded by professionals with backgrounds in Information Systems Engineering, Industrial Engineering, and Computer Science, Total Home Windows and Doors approaches window manufacturing with technical precision. The UltraSlim Series represents our most advanced application of these principles.

With our manufacturing capacity of 150 windows per day at our 60,000 square foot facility, we’re equipped to produce these sophisticated window systems at scale. Our automated production processes ensure consistent quality across every unit, with computer-controlled cutting and welding that achieves precision tolerances of ±0.015″.

Since establishing our first small office in Toronto in 2010 and acquiring our manufacturing facility in 2023, we’ve continuously invested in the technologies that make innovations like the UltraSlim Series possible. Our January 2025 introduction of the Slim Flat Profile 2.78 window marks a significant milestone in this journey.

For a technical consultation or detailed performance specifications for your specific application, visit our showroom or contact us for in-depth analysis.

Read our expert articles on choosing, installing, and maintaining the perfect windows for your home.