When shopping for new windows or planning home renovations in Ontario, understanding R value becomes essential for making informed decisions about your home’s energy efficiency. R value measures thermal resistance—the ability of materials to resist heat flow through your building envelope. Higher R values indicate superior insulating performance, helping reduce heating and cooling costs whilst maintaining comfortable indoor temperatures year-round. For Ontario homeowners facing extreme seasonal temperature differences, selecting materials with appropriate R values can dramatically improve energy savings and overall comfort.

As Daniel Klein, Project Manager at Total Home Windows and Doors, I’ve witnessed countless homeowners struggle with energy bills because they overlooked the importance of thermal performance in their building materials. Our engineering background, stemming from co-owners Vitaliy Shapiro’s expertise in Information Systems Engineering and Anna Klein’s triple degrees in Engineering, Computer Science, and Education, shapes every recommendation we make about insulation and window selection.

Window Replacement Near Me

Understanding R Values and Thermal Resistance

R value represents the measure of thermal resistance that materials provide against heat transfer. This measurement determines how effectively insulation materials slow the three mechanisms of heat flow: conduction, convection, and radiation. The higher the R value, the better the material performs at maintaining temperature differences between interior and exterior environments.

Unlike U value, which represents the inverse relationship showing heat transfer rate, R value focuses on resistance. Lower U values correlate with higher R values, both indicating superior energy efficiency. Understanding this relationship helps homeowners make cost effective decisions when selecting energy efficient windows and insulation materials.

Temperature plays a crucial role in R value effectiveness. Materials that perform well at moderate temperatures may lose insulating value during Ontario’s harsh winters when outside temperature drops significantly. This variability emphasises why climate zone considerations matter when calculating overall R value for your home’s building envelope.

"Many homeowners focus solely on upfront costs without considering long-term energy savings. Proper R value selection pays for itself through reduced heating and cooling expenses over time." - Cherry Jian, Sales Consultant

Thermal bridging presents another challenge to maintaining effective R values. When heat flows through framing materials like metal studs or window frames, it bypasses insulation, reducing the overall thermal performance of walls and windows. This phenomenon explains why vinyl windows often outperform metal-framed alternatives in thermal efficiency.

Find related services

Types of Insulation Materials and Their R Values

Different insulation materials offer varying R values per inch of installed thickness, making material selection crucial for achieving desired thermal performance:

| Insulation Type | R Value Per Inch | Best Applications | Advantages | Considerations |

| Fiberglass Insulation | 2.9-3.8 | Wall cavity, attic spaces | Cost effective, widely available | Performance decreases with moisture exposure |

| Rigid Foam Insulation | 4.0-6.5 | Exterior walls, basement walls | High R values, moisture resistant | Higher upfront costs |

| Loose Fill Insulation | 2.2-3.6 | Attic spaces, irregularly shaped areas | Fills gaps effectively, good for retrofits | Can settle over time, reducing effectiveness |

Cellulose and other materials made from recycled content offer environmental benefits whilst providing decent insulating value. When combined with proper air sealing, these materials create effective barriers against heat loss and unwanted heat gain.

The choice between materials depends on factors including climate zone requirements, existing wall cavity dimensions, and whether you’re addressing an empty wall cavity or retrofitting around existing insulation. For Ontario homes, achieving adequate thermal insulation often requires combining multiple approaches.

Find related products

Heat Transfer Mechanisms and Insulation Effectiveness

Heat moves through buildings via three distinct mechanisms, each requiring different strategies to minimise energy loss:

Conduction occurs when heat travels through solid materials. Dense materials like metal transfer heat rapidly, whilst materials with lower thermal conductivity, such as foam insulation, resist this transfer. This explains why thermal bridging through metal window frames dramatically reduces insulating performance.

Convection involves heat movement through air circulation. Blown insulation and other materials work by trapping air in small pockets, preventing convective heat flow. However, air space design matters—too much space allows convection currents, whilst insufficient space reduces insulating effectiveness.

Radiation transfers heat through electromagnetic waves. This mechanism becomes particularly important when considering solar heat gain through windows and heat loss through exterior walls during winter months.

"Understanding these heat transfer mechanisms helps us recommend the right combination of insulation materials and window technologies for each specific application." - Eugene Siukayev, Project Manager

Most insulation materials address conduction and convection effectively, but radiation requires special consideration. Radiant barriers use highly reflective surfaces to redirect radiant heat, whilst low E glass incorporates low emissivity coatings to control radiative heat transfer through windows.

The Role of Windows in Home Insulation

Windows represent a critical component in your home’s overall thermal performance, often accounting for 25-30% of heating and cooling energy loss. Understanding how windows contribute to your home’s R value helps optimise energy efficiency and comfort.

Insulating Glass Units (IGUs)

Modern double pane windows and triple pane windows use insulating glass units that combine multiple glass layers with insulating air space between them. This design significantly improves thermal resistance compared to single-pane alternatives.

| Window Type | Typical R Value | U Value | Best Applications |

| Single Pane | 0.9 | 1.1 | Historic preservation only |

| Double Pane | 1.8-3.1 | 0.3-0.6 | Standard residential |

| Triple Pane | 2.5-5.0 | 0.2-0.4 | High-efficiency homes |

Low E Coatings and Solar Control

Low E coatings consist of microscopically thin layers of metal oxides applied to glass surfaces. These coatings dramatically improve insulating performance by reflecting infrared radiation whilst maintaining visible light transmission. The technology allows natural light transmission whilst reducing unwanted heat gain during summer and heat loss during winter.

Different low E coatings target specific performance characteristics:

- Hard coat (pyrolytic): Durable, good for harsh climates

- Soft coat (sputtered): Superior thermal performance, requires sealed units

- Solar control coatings: Optimised for reducing solar heat gain coefficient

Gas Fills and Thermal Performance

Many high-performance windows incorporate argon gas windows between glass layers. Argon gas has lower thermal conductivity than air, improving the insulating value of the air space without affecting visible light or natural light transmission. Some premium applications use krypton gas for even better performance in thinner profiles.

Solar Heat Gain and Climate Considerations

Ontario’s climate presents unique challenges requiring careful balance between preventing unwanted solar heat gain during summer whilst maximising beneficial solar radiation during winter months. The solar heat gain coefficient (SHGC) measures how much solar energy passes through windows, affecting both heating and cooling costs.

Managing solar radiation involves several strategies:

Seasonal Considerations

- Winter: Maximise solar heat gain on south-facing windows to reduce heating loads

- Summer: Minimise solar heat gain to reduce air conditioning demands

- Year-round: Optimise visible light whilst controlling thermal effects

Window Orientation Strategies

Different window orientations require different approaches to solar control:

- South-facing windows benefit from moderate SHGC values (0.35-0.55) to capture winter solar heating whilst preventing overheating during summer months when the sun angle is higher.

- East and west-facing windows should prioritise low SHGC values (0.25-0.40) because they receive intense, low-angle solar radiation that’s difficult to shade effectively.

- North-facing windows can accommodate higher SHGC values since they receive minimal direct solar radiation but still benefit from daylight.

"Proper window selection considering both R value and solar heat gain coefficient can reduce energy consumption by 20-30% compared to basic alternatives." - Alexandr Naumov, Project Manager

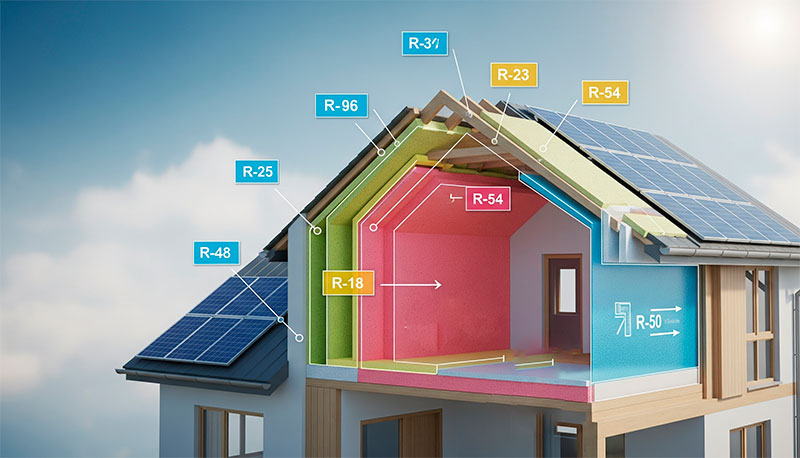

Calculating Heat Loss and Energy Savings

Understanding how much insulation your home needs requires calculating heat loss through various building components. This process helps identify where additional insulation provides the greatest energy savings potential.

Basic Heat Loss Calculation

Heat loss calculation involves several factors:

- Temperature difference between interior and exterior temperatures

- Surface area of walls, windows, and other building envelope components

- U value of each component (inverse of R value)

- Time period for calculation (typically annual or seasonal)

The basic formula: Heat Loss = Area × U Value × Temperature Difference × Time

Identifying Priority Areas

Most Ontario homes show the following priorities for insulation improvements:

- Attic spaces: Often the most cost effective upgrade

- Basement walls: Significant impact on comfort and energy use

- Exterior walls: Important but may require major renovation

- Windows: High impact but higher investment required

- Air sealing: Essential complement to insulation upgrades

Return on Investment

| Improvement Type | Typical R Value Increase | Payback Period | Annual Energy Savings |

| Attic insulation | R-20 to R-50 | 2-4 years | 15-25% |

| Basement walls | R-0 to R-20 | 5-8 years | 10-15% |

| Window replacement | R-2 to R-4 | 8-15 years | 10-20% |

Professional Installation and Performance

Achieving rated R values requires proper installation techniques. Poor installation can reduce insulation effectiveness by 50% or more, negating the benefits of high-performance materials.

Common Installation Issues

Compression reduces the insulating value of fibrous materials by eliminating the air spaces that provide thermal resistance. This commonly occurs when stuffing too much insulation into wall cavities or compressing batts during installation.

Gaps and voids allow heat flow through uninsulated areas, creating thermal bridging that bypasses insulation entirely. Even small gaps can dramatically reduce overall thermal performance.

Moisture problems can develop when insulation installation doesn’t include proper vapour barriers or air sealing. Moisture reduces insulating effectiveness and can lead to mold growth and structural damage.

Quality Assurance Measures

Professional installation includes several quality measures:

- Thermal imaging to identify installation gaps and thermal bridging

- Blower door testing to measure air leakage and identify sealing needs

- Moisture monitoring to ensure proper vapour barrier installation

- Follow-up inspections to verify long-term performance

At Total Home Windows and Doors, our installation teams receive ongoing training in proper techniques for both insulation and window installation. Our lifetime warranty on workmanship reflects our confidence in installation quality.

Optimising Your Home's Thermal Performance

Creating an effective thermal envelope requires coordinating insulation materials, window selection, and air sealing strategies. This integrated approach maximises energy efficiency whilst maintaining comfort and indoor air quality.

Whole-House Approach

Rather than addressing individual components separately, successful thermal optimisation considers how different elements work together:

- Building envelope continuity ensures insulation and air barriers connect properly at transitions between walls, windows, doors, and other components.

- Thermal bridge minimisation involves designing details that reduce heat flow through structural elements and connections.

- Moisture management prevents condensation problems that can reduce insulation effectiveness and cause structural damage.

Technology Integration

Modern homes benefit from integrating multiple technologies:

- Smart thermostats optimise heating and cooling based on occupancy and weather

- Energy recovery ventilators maintain air quality whilst minimising energy loss

- Advanced window controls automatically adjust for changing solar conditions

- Monitoring systems track energy use and identify performance issues

Future-Proofing Considerations

When planning insulation upgrades, consider future needs and technologies:

- Climate change adaptation may require different strategies as Ontario’s climate continues evolving.

- Energy code updates regularly increase minimum insulation requirements for new construction and major renovations.

- Technology advancement in materials and installation techniques continues improving cost effectiveness and performance.

- Utility programs may offer incentives for high-performance upgrades, improving return on investment.

Understanding R value and thermal performance helps Ontario homeowners make informed decisions about insulation and window upgrades. Whether you’re planning new construction, major renovations, or targeted efficiency improvements, proper attention to thermal resistance creates more comfortable homes with lower energy costs. Consider consulting with professionals who understand local climate challenges and building science principles to optimise your home’s thermal performance for both current comfort and long-term value.

For more information about energy-efficient windows and doors, explore our window replacement options or visit our showroom to see the latest technologies in person. Or

Frequently Asked Questions About R-Value

Is an R-value of 2.5 good?

An R-value of 2.5 is adequate for windows with low e glass but insufficient for walls. Most uninsulated wood frame wall assemblies require R-13 minimum, whilst quality insulation should achieve much higher values for optimal thermal performance.

Is a higher R-value better?

Yes, higher R-values always provide superior thermal resistance and reduce heat transfer more effectively. However, cost-effectiveness matters—adding insulation beyond certain thresholds may not justify expenses, especially when upgrading individual layers of existing building envelope systems.

What does R-value of 5 mean?

R-value of 5 indicates moderate thermal resistance, suitable for premium windows or thin insulation applications. This value means the material resists heat flow five times better than a material with R-1, significantly improving energy efficiency compared to basic alternatives.

What is a good R-value for insulation?

Good R-values vary by application: attics need R-40 to R60, exterior walls require R-20 to R-24, and basements benefit from R-12 minimum. These values ensure adequate thermal performance whilst remaining cost-effective for Ontario’s climate zone requirements.

What is the R-value in insulation in Canada?

Canadian insulation standards, following united states department energy guidelines, require minimum R-20 for walls and R-40 for attics in most climate zones. However, high-performance homes often exceed these minimums to reduce heat transfer and achieve greater energy savings.

Should I install R19 or R30 in my attic?

Choose R-30 for Ontario attics. While R-19 meets minimum codes, R-30 provides significantly better thermal performance and energy savings. The additional investment pays back through reduced heating costs, especially when combined with proper air sealing and exterior siding upgrades.

Is a higher or lower R-value better?

Higher R-values are always better for thermal performance. Like uv light protection or avoiding unnecessary drill holes during installation, maximizing insulation value improves comfort and efficiency. Even when installing new siding, prioritizing higher R-values delivers long-term benefits through reduced energy consumption.